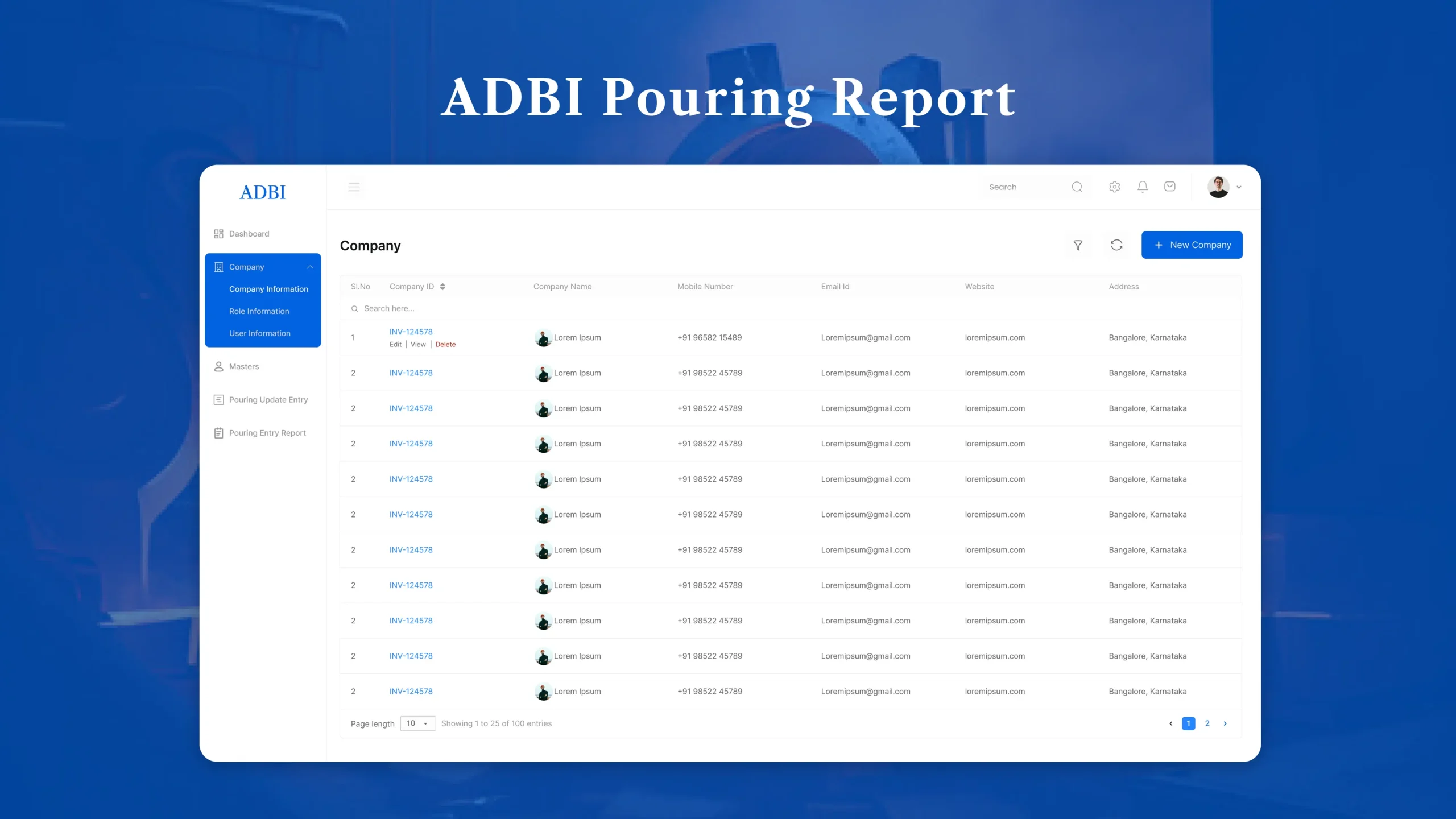

ADBI Pouring Management Web Application

Background:

ADBI, a leading automobile foundry, recognized the need to modernize and optimize their pouring entry management processes. Manual methods for tracking pouring activities, managing inventory, and scheduling were proving to be time-consuming and error-prone. To address these challenges, the ADBI Pouring Management Web Application project was initiated. The aim was to create an integrated solution that automates pouring entry processes, improves inventory tracking, and optimizes scheduling to enhance overall foundry operations.

Objective:

The primary objective of the project was to develop a web application tailored for pouring management in the automobile foundry. Key goals included:

- Automation of Pouring Entry: Implementing a digital system to automate and streamline the pouring entry process, reducing errors and enhancing efficiency.

- Enhanced Inventory Tracking: Developing a robust inventory tracking system to provide real-time visibility into raw materials and finished products.

- Optimized Schedule Management: Improving coordination between pouring activities and other foundry operations through an integrated scheduling module.

- Operational Efficiency: Minimizing manual interventions and improving overall operational efficiency within the foundry.

Challenges:

Several challenges were identified at the project’s inception:

- Manual Data Entry: Manual pouring entry processes led to errors, delays, and inconsistencies in data.

- Inventory Management: Lack of real-time inventory tracking resulted in difficulties in maintaining accurate stock levels.

- Scheduling Coordination: Coordinating pouring schedules with other foundry operations proved challenging without a centralized system.

- Technology Adoption: Ensuring seamless adoption of the new web application among foundry staff required overcoming resistance to change.

Solutions:

A set of comprehensive solutions were implemented to address the identified challenges:

- Digital Pouring Entry System: A user-friendly digital pouring entry system was developed to replace manual processes, reducing errors and providing real-time data.

- Centralized Scheduling Module: A centralized scheduling module was implemented to coordinate pouring activities with other foundry operations, improving overall efficiency.

- Change Management: A change management strategy, including training programs and communication initiatives, was implemented to facilitate smooth user adoption.

Results:

The implementation of the ADBI Pouring Management Web Application led to significant positive outcomes:

- Error Reduction: The digital pouring entry system significantly reduced errors associated with manual data entry, improving data accuracy.

- Real-time Inventory Visibility: RFID and barcode integration provided real-time tracking of inventory, leading to better control and management of raw materials and finished products.

- Improved Scheduling Coordination: The centralized scheduling module improved coordination between pouring activities and other foundry operations, leading to increased operational efficiency.

- Successful User Adoption: The change management initiatives resulted in successful user adoption, with staff embracing the new web application.

Conclusion:

The ADBI Pouring Management Web Application project successfully addressed the challenges faced by the automobile foundry, providing a holistic solution for pouring entry management, inventory tracking, and schedule optimization. The project not only improved operational efficiency but also demonstrated the transformative power of technology in industrial processes. The commitment to change management, technology integration, and ongoing support showcased the project’s success in meeting its objectives. This case study serves as a testament to the positive impact of digital transformation in enhancing operations within the manufacturing sector.

Web Development

Web Development

App Development

App Development

IT Consulation

IT Consulation

UI/UX Design

UI/UX Design

Ecommerce

Ecommerce

Content Marketing

Content Marketing

DevOps Services

DevOps Services

Software Development

Software Development

Digital Marketing

Digital Marketing

Social Media Marketing

Social Media Marketing

Search Engine Optimization

Search Engine Optimization

AWS Managed Services

AWS Managed Services

QA And Software Testing

QA And Software Testing

Local Search Optimization

Local Search Optimization

Technology Outsourcing

Technology Outsourcing

Metaverse Development

Metaverse Development

Web 3 Consulting

Web 3 Consulting

IoT App Development

IoT App Development

VR App Development

VR App Development

IT Staff Augmentation

IT Staff Augmentation

Startup App Development

Startup App Development

Saas App Development

Saas App Development

Low Code Development

Low Code Development

Product Engineering

Services

Product Engineering

Services

Custom CRM Development

Custom CRM Development

Offshore Development

Center (ODC)

Offshore Development

Center (ODC)

Machine Learning

Development

Machine Learning

Development

Blockchain App Development

Blockchain App Development

Blockchain In Identity Management

Blockchain In Identity Management

Artificial Intelligence

Development

Artificial Intelligence

Development

Dedicated Development Team

Dedicated Development Team

Strategic Mobile

Consulting

Strategic Mobile

Consulting

Scrum

Scrum

DevOps

DevOps

Lean

Lean

Kanban

Kanban

V-Model

V-Model

Waterfall Model

Waterfall Model

Design Thinking

Design Thinking

Agile Development

Agile Development

Prototype Methodology

Prototype Methodology

Rapid Application Development (RAD)

Rapid Application Development (RAD)

Feature-Driven

Development (FDD)

Feature-Driven

Development (FDD)

Dynamic Systems

Development Method (DSDM)

Dynamic Systems

Development Method (DSDM)